Advanced Brushless Motor and Materials Enhance Miniature Diaphragm Pump Capabilities

Advanced Brushless Motor and Materials Enhance Miniature Diaphragm Pump Capabilities

Miniature diaphragm pumps have had their performance and operational life limited by standard elastomer mechanical properties and DC Brushless motor designs. As fluidic system developers have demanded smaller component envelopes, diaphragm pumps have incurred increased challenges to increase performance and life requirements.

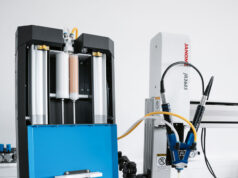

Hargraves Technology, www.hargravesfluidics.com, a global leader in advanced fluidic technologies and system solutions, has achieved breakthrough advances in brushless DC motors and diaphragm elastomer materials. The Hargraves BTC, CTS and LTC series of miniature diaphragm pumps offer a series of brushless DC motor driven pumps, vacuum pumps and compressors to handle air, gases and several liquid applications. The Hargraves innovative designs and advanced fluidic technologies offer the highest performance in the smallest package size available. These diaphragm pump series uses a proprietary advanced diaphragm elastomer (AEPDM) and superior brushless motor design to set the highest benchmark for service-free miniature diaphragm pump operation that exceeds 20,000 hours.

Advanced Brushless DC Motor Technology

Brushless DC Motors (BLDC) developed by Hargraves are designed to endure long life applications to achieve high reliability and performance under challenging operational loads. The Hargraves engineering team took the initiative to improve standard motor designs and manufacturing processes to optimize efficiencies and endurance. Both a “short stack” and “long stack” configurations were produced for different torque requirements. The Long Stack brushless DC motor, for instance, consists of magnets and windings that are twice the length and is used for exceptionally high load applications.

Brushless motors, as the name implies, do not use brushes for commutation. Instead, they are electronically commutated. The stator consists of stacked steel laminations that are axially cut along the inner periphery. Numerous coils are interconnected to form each winding. An even number of magnetic poles are produced from each of these windings that are distributed over the stator periphery. The rotor is a permanent magnet with alternating magnetic poles built in.

To rotate a DC motor, the windings need to be energized in sequence. The position of the rotor will determine which winding will need to be energized. Unlike brush motors that commutate by mechanical switching, brushless motors position using an electronic sensorless method or by utilizing Hall effect sensors. These sensors are embedded on the stationary part of the motor and monitor the exact position on the rotor’s position. As the rotor’s magnetic poles rotate near the Hall effect sensors, they give a high or low signal that signifies a north or south pole is passing near the sensors. The exact sequence of commutation can be determined from the combination of the three signals the sensors are reading. Each commutation sequence has current entering one of the windings resulting in positive magnetic flow, current exiting a second winding resulting in a negative magnetic flow, and a third winding that would be non-energized. The direction of the magnetic flow would affect the winding’s polarity. The interaction of these changing poles of the magnetic field between the stator and the permanent motor produces the torque that turns the motor’s shaft.

As the requirements for miniature diaphragm pumps to fit in even smaller package envelopes, the motors powering these systems have had to become smaller. These smaller brushless motor sizes will most likely use sensorless commutation methods since Hall effect sensors take up more space. It should be noted that sensorless motors are limited to the initial startup torque they can produce. Brushless DC motor applications that require restarts under a high load will need to utilize Hall effect sensors with an instant start capability. Therefore, to achieve very small motor size, there may need to be a tradeoff on restart capabilities.