When Travtec Packaging Engineering started developing a new high performance hygienic seal film printing machine for a major medical device company, it knew that precision linear indexing would be the key to success, so called in automation components specialists Hoerbiger-Origa for consultation.

Hoerbiger-Origa worked with Travtec to develop a printer that could traverse back and forth across a moving web of clear film, applying vital consumer information and branding just before the film seals containers prior to lidding.

The printing on the film had to be positionally accurate relative to the container and timed to the sequence control of the overall machine. As the containers index through a filling station with typically 5-10 filling heads, the printer is required to traverse with a demanding intermittent motion cycle at a repeatability of 0.1mm, and this suggested that a servo driven electric linear actuator would be required to achieve the necessary accuracy and repeatability.

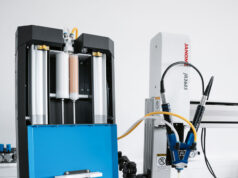

The design that the engineering team picked uses a standard thermal ribbon printer mounted on a screw-driven Hoerbiger-Origa actuator with a servo motor and controller, so that it can traverse across the web.

Hoerbiger-Origa Corporation

100 West Lake Drive

Glendale Heights, IL 60139

800-695-5984