Industrial accidents occur all too often in a variety of workplace environments. Machine operators and construction workers regularly face potential accidents from moving machine parts, hazardous chemicals and unsafe working conditions. And the toll it takes on domestic industry productivity is telling. Recent studies, by the National Safety Council indicate that production time lost due to on-the-job injuries costs industry approximately $142.2 billion per year.

Workplace injuries can be significantly reduced with failsafe equipment and valves, adequate warning systems and controls designed to reduce, interrupt or prevent equipment failures altogether.

Addressing Customer Concerns

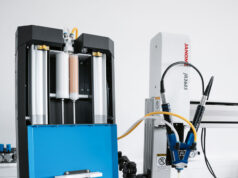

One cost-effective solution to the industrial safety issue in pneumatic applications is the rod lock cylinder, which is a piston-operated clamp used to hold a load in position during emergency-stop (E-Stop) conditions or when an air supply might be accidentally disconnected from a system. In an E-Stop condition, all outputs go dead, and the spring-activated rod lock is one of the few functioning components on the machine.

Many applications that employ rod lock cylinders include clamping, precision static load holding and ergonomic tooling.

Clamping functions are often used in machine fixture and conveyor pallet applications. Many customers use Parker’s P1D rod lock cylinders to function as a toggle clamp mechanism in automated assembly lines. In one case, a conveyor pallet is automatically shuttled to each station along the assembly line. Once in position at each station, the cylinder actuates a toggle mechanism to clamp the pallet. Then, air pressure is removed from the cylinder and the rod lock. The pallet fixture is held in place by the rod lock for the machining operation.

Rod lock cylinder use in welding systems has helped more than one manufacturer improve productivity. A process for welding heavy structural steel I-beams with common lengths longer than eight feet originally included manual clamping and centering operations. Now, through the use of 100mm bore P1D rod lock cylinders, they are able to automate the process and reduce cycle time.

First, I-beams are automatically pushed and held in position with air cylinders. Next, they are clamped at several different points along the I-beam by pairs of rod lock cylinders. Because welding in this application produces thermal deformation of the I-beams, which results in beam movement and poor weld quality, a high clamping force must be present and consistent. To accommodate this requirement, air pressure is removed from the cylinder and rod lock, engaging the mechanical rod lock and keeping the I-beams exactly in place without any potential rod movement from air compressibility issues. After these steps are complete, with the use of a few hand operated air valves (customer choice), welding operations can proceed, and the system ensures a consistent quality product every time.

In precision static load-holding instances, a rod lock cylinder serves as a necessary preventive measure in ensuring worker safety during manufacturing operations. These instances include press applications to hold platen or tooling, applications in which vertical loads must remain stationary for extended periods of time, applications where “zero potential energy” is required (i.e., no pilot-operated check valves are allowed to trap air pressure in the cylinder), or applications where position must be maintained within .002” for extremely low backlash.

Ergonomic tooling uses cylinders as a mechanical safety measure to balance overhead tooling loads. These applications typically involve heavy or odd-shaped loads that require a manipulator to assist operators in handling the load. If air pressure is lost anywhere within the system, loads could easily fall and potentially harm workers. In most cases, the manufacturer must take extra steps to ensure that if an E-Stop condition occurs, an external safety device is utilized. Incorporating this safety functionality into the rod lock cylinder simplifies the design and reduces the number of components in the system.

Rod locks provide a mechanical locking system that has the ability to hold loads indefinitely. Air, on the other hand, will eventually bleed through any seals. In the absence of an appropriate air signal, full holding force is applied to the piston rod. When a minimum of 60 PSIG air signal is present, the locking device is released. Thus, rod lock cylinders provide precise load holding capacity with virtually zero backlash and feature high accuracy for the most demanding applications. But even more importantly, these devices can serve as an effective solution to plant safety issues.

Integrating Machine Safety Solutions

Equipment faults such as sticky valves, hose failures, stored energy or blocked flow paths can lead to machine tool failure and potential exposure of plant personnel to unacceptable danger levels.

Rod lock cylinders are regularly used to safely hold loads in place and prevent tooling from being dropped or damaged. They provide load-holding capacity in both directions, regardless of stroke position. Air cylinders have different capacities to move a load that corresponds to the position of the piston rod. The output force of the actuator is higher when extending. Therefore, with a pilot-operated check valve, the loading condition changes depending on the direction of motion within the cylinder. Using a rod lock, however, ensures that load-holding capacity remains constant, regardless of motion direction.

For a variety of reasons, some facility managers prefer primitive, homemade devices or customized safety device systems from the OEM. In one example, a 3-position directional air valve with a “closed center” position locks the current air pressure into both sides of the cylinder. This fails to eliminate rod and machine movement from inertia, external forces and air compressibility issues. Another example relies on an additional cylinder to side-load the rod with friction material or to counteract/ follow the primary cylinder’s stroke. Some special systems use single acting cylinders to engage a pin into cross-drilled holes in the primary cylinder’s piston rod, but significant movement still occurs and the resultant shock load can shear this pin and dislocate the part or other machine members. Also seen are mating gear racks that are forced apart by a secondary single-acting cylinder and, when air pressure is below a certain pressure, the racks are mated to hold the load mechanically. There are too many mechanical blocking designs to address here that act as the hard-stop for machine movement but may not be effective enough to guarantee safety.

Most of these safety measures, however, are unproven, expensive and difficult to diagnose. They have never been laboratory tested for life and wear. They are often implemented as a quick fix and may not be as safe as initially thought at installation. In addition, specialized customer safety devices and systems require intensive OEM interface, testing and final acceptance evaluation. As an alternative to this expensive, time consuming effort, safety devices can be bundled into commercially available cylinders with outstanding performance results.

Most of these safety measures, however, are unproven, expensive and difficult to diagnose. They have never been laboratory tested for life and wear. They are often implemented as a quick fix and may not be as safe as initially thought at installation. In addition, specialized customer safety devices and systems require intensive OEM interface, testing and final acceptance evaluation. As an alternative to this expensive, time consuming effort, safety devices can be bundled into commercially available cylinders with outstanding performance results.

For added flexibility in pursuing a plant safety solution, existing systems can also be retrofitted with rod lock cylinders in two major ways. First, please note that the rod lock version of a cylinder is always longer than the base cylinder model; therefore, the rod lock cylinder will only properly “drop-in” interchange with the base cylinder if it was originally mounted at the head end (rod end) of the cylinder. Common mounts that facilitate this “drop-in” interchange include NFPA MF1 (Head Rectangular Flange) and MX3 (Tie Roads Extended Head End) mounts. Other mounts may require a minor fixturing change. In another method, if the original cylinder is of a single rod design, and the rod end dimensions and location are fixed to the application, the cap end can be converted into a double rod cylinder with the rod lock on this new or secondary head end.

Power, Precision, Performance

National Fluid Power Association (NFPA)-rated rod lock cylinders, such as the Parker 3MAJ/4MAJ series, possess a number of unique performance characteristics. For example, bolt-on modularity enables one cylinder or lock to be removed or replaced without changing the entire unit. The rod lock may be removed without affecting the base cylinder. This modular construction is important for customized installations or for cylinder servicing.

Rod lock cylinders are available in standard rod diameters, as well as oversized versions, depending on the application. This allows for improved column strength when required and permits using a smaller package size rather than selecting a larger bore sized unit due to larger rod or rod end thread requirements.

Rod lock cylinders are available in standard rod diameters, as well as oversized versions, depending on the application. This allows for improved column strength when required and permits using a smaller package size rather than selecting a larger bore sized unit due to larger rod or rod end thread requirements.

A manual override shaft provides rod lock release when equipment is in non production mode. During installation or maintenance, this feature enables the cylinder to automatically spring back into lock mode when a tool, such as a wrench, is removed from the shaft.

Leading rod lock cylinders include guide units for both NFPA and ISO (International Standard Organization) packages to provide off the shelf stock availability, easier customer installation, significant side load capability, as well as pick-and-place applicability where precise load positioning and holding capacity are required.

There is a clear and pressing need to integrate comprehensive safety equipment components into overall systems across the board in manufacturing processes to maintain uninterrupted equipment functionality, avoid failure and resulting downtime, and ensure the continued productive capacity, quality and safety of the workforce. As illustrated in this article, rod lock cylinders are a cost-effective solution to the industrial safety issues in pneumatic applications.

Testing Illustrates Safety with Cylinders

E-Stop applications are common on industrial machines in the automotive industry. And there has been an age-old concern about using pneumatic cylinders in vertical applications. A long-time customer (an OEM that sells automotive assembly fixtures and other special machinery to its customers) recently faced this issue. One of the OEM’s customers was concerned about safety issues when using pneumatic cylinders in vertical applications. The OEM’s customer had a specific application for a rod lock to be rated for dynamic braking. The customer’s current rod lock cylinder supplier was unwilling to review the application. On the customers’ behalf, the OEM, in conjunction with Parker, performed an engineering study of different brands of pneumatic rod lock cylinders for potential failure in dynamic braking applications. Test results led to Parker’s selection as the preferred supplier of all rod lock cylinders used in this application.

Parker supplied P1D rod lock cylinders to the OEM for the testing process. After the initial braking distance was determined, a “failure” was identified as any increase from this initial distance (which would indicate that the rod lock is slipping, albeit slightly, from rod chrome wear). The P1D rod lock cylinder completed 527,346 cycles before exceeding test parameters. The competitor’s rod lock cylinder failed at only 146,820cycles. Notably, in order to dynamically brake with the specified test load of 500 pounds, the competitor’s rod lock cylinder air pressure was reduced to 20 PSIG while the Parker rod lock cylinder pressure was maintained at the original air pressure of 50 PSIG, illustrating a much higher braking force. In addition, the average braking distance was 0.45 inches, while the competitor’s average distance was 0.52. In this application, the P1D addressed all related safety issues.

About the authors:

Karl Hay is regional sales manager for Parker with 12 years of experience with the company. Rade Knezevic is product marketing manager for Parker with 14 years of experience with the company. Visit www.parker.com for more information.